What is DAQ?

Part 1: Understanding DAQ – The Essential Tool for Data Acquisition

In today’s fast-evolving world of technology, data has become the driving force behind innovation. Whether it’s precision measurement in laboratories, automation on industrial production lines, or cutting-edge scientific research, data acquisition is the foundation of all data processing and analysis. A DAQ (Data Acquisition System) is the core technology that enables this critical step.

1. What is DAQ? Redefining the “Eyes” and “Ears” of Data Acquisition

A DAQ system is an electronic platform that converts analog signals from the physical world (such as voltage, current, temperature, pressure, and sound) into digital signals for collection, processing, storage, and transmission. Acting as the “sensory system” of a device, it captures raw data from complex physical environments and provides accurate digital inputs for subsequent analysis, control, and decision-making.

Technically, a DAQ system typically consists of four main components:

- Analog Front End (AFE): Conditions incoming analog signals—amplifying, filtering, matching impedance, and adjusting range—to ensure they meet the quality requirements for further processing.

- Analog-to-Digital Converter (ADC): Converts conditioned analog signals into digital form. It is a key component that determines sampling precision and speed.

- Field-Programmable Gate Array (FPGA): Handles high-speed data processing, real-time algorithm execution, and system control, supporting flexible and customizable development.

- Trigger Module: Precisely controls the start of data acquisition based on predefined conditions such as signal thresholds, edge detection, or external events, ensuring capture of critical signal segments.

2. How DAQ Works: The Translator from Analog to Digital

The core workflow of a DAQ system can be summarized in four steps: Sense – Convert – Process – Output.

- Signal Conditioning: The analog front end pre-processes incoming signals—for instance, amplifying weak signals to be within the ADC’s input range, filtering out high-frequency noise, or isolating DC bias via coupling methods (AC/DC).

- Analog-to-Digital Conversion: The ADC digitizes the signal using a defined sampling rate (e.g., how many times per second) and resolution (e.g., 12-bit, 16-bit). Sampling rate affects the ability to capture high-frequency components (as per Nyquist theorem), while resolution determines the quantization accuracy.

- Digital Processing and Storage: The FPGA processes the digital data in real time (e.g., filtering, spectrum analysis, feature extraction), or temporarily stores it in high-speed memory (e.g., DDR4). Data is then transferred to a host computer or controller via interfaces such as PCIe or Gigabit Ethernet.

- Trigger Control: External (sensor-based) or internal (signal threshold) triggers ensure acquisition only occurs during target events, avoiding unnecessary data overload.

3. Types of DAQ Systems: A Toolbox for Custom Data Acquisition

By structural form, DAQ (Data Acquisition) systems can be classified into the following types:

- Data Acquisition Modules: Compact embedded devices that support standalone operation or can be paired with controllers. They are ideal for space-constrained environments such as the Industrial Internet of Things (IIoT) and portable instruments.

- Data Acquisition Cards: Boards installed in the PCIe slots of industrial PCs or servers. Relying on the computing power of the host, they enable high-speed data processing, making them suitable for high-precision laboratory measurements or real-time monitoring.

- Data Acquisition Boxes: Integrated standalone devices with built-in power supplies, processors, and multiple communication interfaces. They support plug-and-play functionality and are well-suited for distributed deployment in industrial field environments.

4. Core Application Scenarios of DAQ: The Technology Foundation Driven by Data

The value of DAQ (Data Acquisition) systems spans across multiple fields such as scientific research, industrial automation, and biomedical applications:

- Scientific Research: Capture transient signals (e.g., laser pulses, particle collision waveforms) in physics experiments, and monitor strain and temperature changes in material science, providing critical data to support theoretical validation.

- Industrial Automation: Monitor real-time sensor data on production lines (e.g., pressure, vibration, current) to enable predictive maintenance, process optimization, and quality control—making DAQ a key component of intelligent manufacturing.

- Test & Measurement:Analyze RF signals, power ripple, and high-speed bus signals during electronic product development to ensure that performance meets design specifications.

- Biomedical: Acquire physiological signals such as ECG, EEG, and EMG for disease diagnosis, rehabilitation device development, or clinical data logging in drug trials.

- New Energy: Monitor charge/discharge curves and voltage balancing during battery testing, and analyze harmonic distortion and efficiency in photovoltaic inverter testing—supporting the evolution of green energy technologies.

Part 2: Smartgiant DAQ Product Portfolio – Combining High Performance with Customization

As an innovative company focused on electronic testing and measurement technologies, Smartgiant offers a full range of DAQ products built for high-speed acquisition, high-precision measurement, and flexible deployment. Our “hardware platform + software customization” model meets the unique demands of customers across industries. Below is a detailed breakdown of our DAQ solutions in terms of product categories, core features, and application scenarios.

1. Product Overview

Smartgiant offers both advanced DAQ systems and a range of versatile FPGA boards, designed to empower engineers with flexible hardware solutions for high-speed data processing. Our DAQ family includes three form factors—all built on FPGA architecture for high-performance signal processing and customizable development interfaces:

1.1 High-Speed DAQ Card –SG1227 PCIe Acquisition Card

Designed for high-frequency signal capture, supports dual-channel synchronous acquisition up to 5GSa/s (in single-channel interleaving mode), with 500MHz analog bandwidth. Ideal for capturing nanosecond-scale transients. Powered by Xilinx XCKU040 FPGA with 4GB onboard DDR4 and PCIe 3.0 ×8 interface for high-throughput real-time transmission.

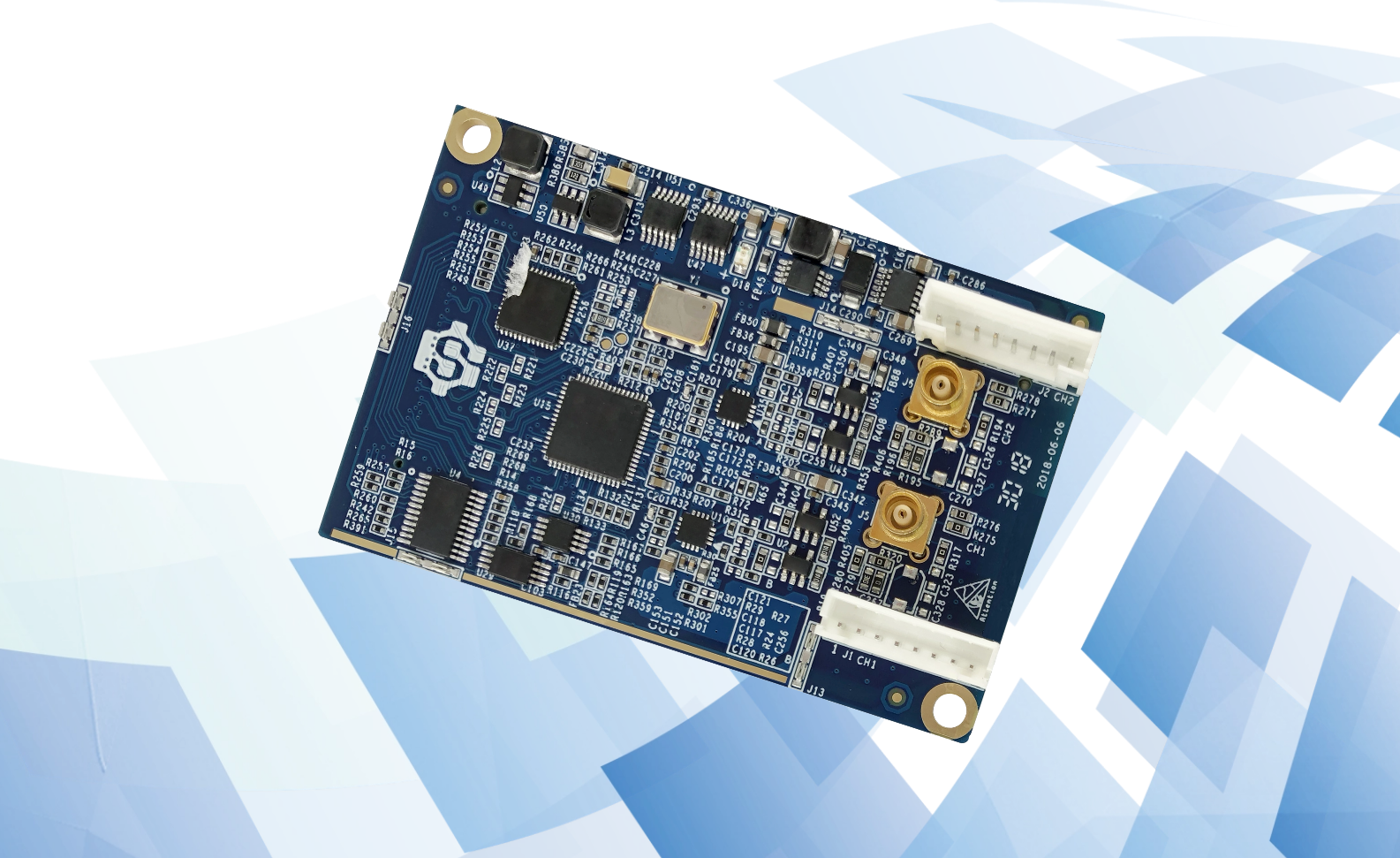

1.2 High-Precision DAQ Module –High-Speed Data Acquisition Module

Targeted at mid-speed, high-accuracy applications. Features 12-bit resolution, 125Msps sampling rate, and -3dB bandwidth of 30MHz. Input range ±0.9V. Customizable FPGA programming supports industrial measurement and medical device development with high signal fidelity.

1.3 Integrated DAQ Box – SG2168 High-Speed Acquisition BOX

Built for field deployment, powered by Xilinx high-performance MPSoC. Supports 500MSps, 14-bit resolution, and integrates Gigabit Ethernet, CAN, RS485, etc. EMI-shielded for reliable operation in harsh environments.

2. Key Features

2.1 High-Performance Hardware to Meet Demanding Specs

- Optimal Balance of Sampling Rate and Bandwidth:

SG1227 enables 5GSa/s for capturing laser radar pulses; High-Speed Data Acquisition Module offers 12-bit resolution for 0.1% quantization precision—ideal for low-amplitude signal acquisition.。 - Wide Dynamic Range and Low Noise Design:

Input range from 50mV to 5V (SG1227 supports 9 programmable ranges). Low-noise AFE ensures SNR from 39dB (SG1227 PCIe Acquisition Card) to 56.8dB (DAQ BOX) under 10MHz input—capturing both weak and strong signals accurately. - Large-Capacity Storage and High-Speed Transmission

4GB DDR4 onboard memory enables long-duration acquisition; PCIe 3.0 ×8 delivers up to 8GB/s theoretical bandwidth for low-latency waveform display and spectrum analysis.

2.2 FPGA Customization for Diverse Applications

- Hardware Acceleration and Embedded Algorithms:

Xilinx FPGA logic allows real-time algorithm implementation (e.g., DDC, FIR filtering, peak detection) without relying on the host PC—minimizing latency. In semiconductor testing, this enables real-time edge computing for defect detection.。 - Multi-Card Synchronization and System Scalability:

Supports external clock sync (100MHz reference or 2.5GHz sample clock), enabling multi-channel parallel acquisition—suitable for radar arrays and modal analysis requiring spatial synchronization.

2.3 Intelligent Triggering and Precise Control

- Versatile Trigger Modes:

Supports external (e.g., TTL), channel-based (edge/level threshold), and software triggers. Configurable for rising/falling edge or level-based events—enabling precise data capture even in complex signal environments. For example, in LiDAR, external triggers sync laser emission with signal acquisition to avoid capturing irrelevant data. - Trigger Signal Conditioning:

Trigger input supports DC coupling with 50Ω impedance, compatible with signal amplitudes from 0.5Vpp to 5Vpp—adaptable to various sensor outputs.

2.4 Modular Design and Rich Interfaces for Seamless Integration

- Flexible Form Factors:

DAQ cards (PCIe) for lab desktop integration; DAQ modules for compact embedded devices; DAQ boxes (PoE + industrial bus support) for direct deployment on production lines without extra IPCs. - Standard Interfaces and Protocols:

Offers Gigabit Ethernet, USB 3.0, PCIe 3.0, and supports LabVIEW, MATLAB, Python, with SDKs and drivers to simplify secondary development.

3. Application Scenarios

3.1 New Energy: Battery and Power Conversion Testing

- Battery Charge/Discharge Testing:

High-Speed Data Acquisition Module captures voltage/current curves with 12-bit accuracy to detect millivolt-level variations and identify cell inconsistencies. SG1227 PCIe acquisition card monitors nanosecond transients during IGBT switching in inverters—assessing EMC performance. - PV Inverter Efficiency Analysis:

The SG2168 DAQ BOX measures harmonic distortion (THD) and power factor using 200MHz bandwidth and 14-bit resolution—ensuring grid compliance.

3.2 Biomedical: Precise Physiological Signal Acquisition and Device Development

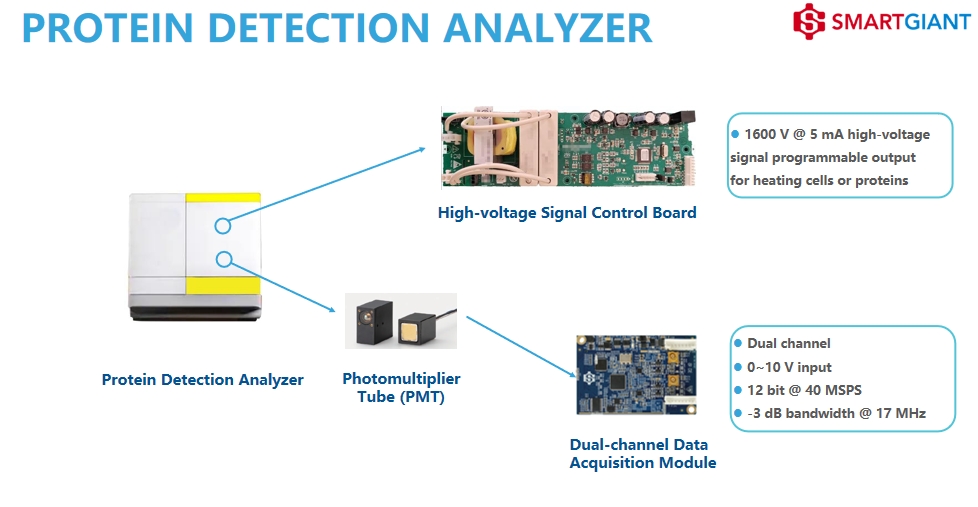

- Protein Detection and Analysis:

In protein detection analyzers, the high-voltage signal control board delivers a programmable high-voltage output of 1600 V @ 5 mA to precisely heat cells or proteins. Paired with a dual-channel data acquisition module (0–10 V input, 12-bit @ 40 MSPS, -3 dB bandwidth @ 17 MHz), it enables high-precision signal acquisition, providing reliable data support for protein structure analysis and detection.

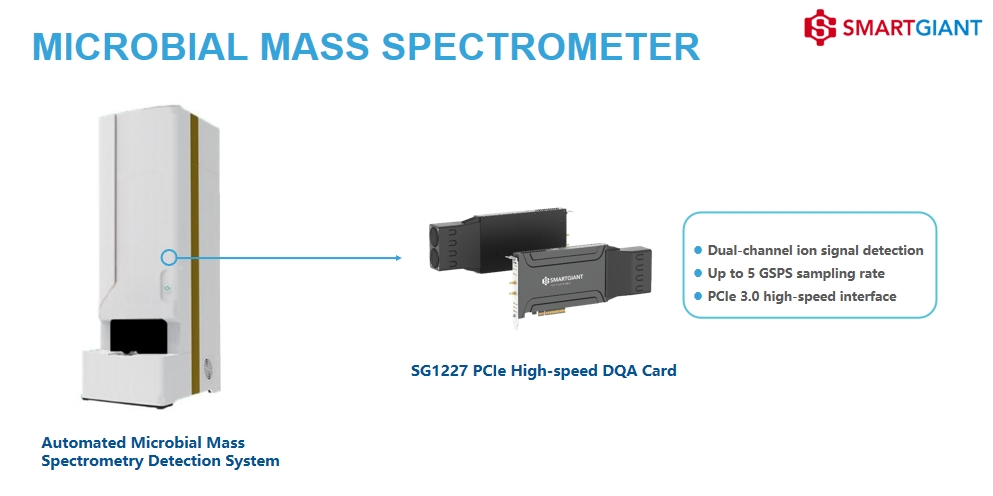

- Microbial Mass Spectrometry Detection:

The fully automated microbial mass spectrometry detection system utilizes the SG1227 PCIe high-speed acquisition card to perform dual-channel ion signal detection at a sampling rate of up to 5 GSPS. With the PCIe 3.0 high-speed interface enabling rapid data transmission, the system ensures high-precision analysis of microbial mass spectrometry, significantly improving the accuracy and efficiency of microbial detection.

3.3 Industrial Automation: Smart Production and Equipment Diagnosis

- Motor Vibration Analysis:

Dual-channel modules (e.g., high-speed data acquisition modules) detect bearing-related high-frequency vibrations (10–30MHz). Combined with spectral analysis, they enable early fault detection. - Semiconductor Wafer Testing:

Sub-nanosecond resolution of high-speed DAQ cards enables detection of transient current changes during probe-wafer contact—helping identify micro-defects and improve yield.

Conclusion: DAQ Unlocks Data Value with Modular Solutions for Diverse Scenarios

In industries such as industrial automation, new energy, and medical equipment, Data Acquisition (DAQ) systems serve as a cornerstone of digital transformation. Smartgiant’s modular DAQ system combines high-performance hardware—supporting ultra-high-speed sampling up to 5GSa/s and 12-bit high-precision measurement—with a flexible architecture featuring multi-channel synchronization and real-time processing. This enables tailored solutions for industrial data collection, new energy testing, and medical signal acquisition, empowering end-to-end efficiency from signal capture to intelligent decision-making.

Take Action Now—Unlock the Power of Your Data!

→ Contact our technical experts for a customized DAQ solution and a free demo. Harness high-precision data acquisition and real-time processing to drive innovation in R&D and optimize production lines—step into a smarter, data-driven future today!

Contact Us

Smartgiant Technology 1800 Wyatt Dr, Unit 3, Santa Clara, CA 95054.

Email: info@smartgiant.com

Contact Us

Smartgiant Technology 1800 Wyatt Dr, Unit 3, Santa Clara, CA 95054.

Email: info@smartgiant.com