How MIPI RFFE Controllers Improve RF Front-End Test Efficiency

1. The Hidden Challenge Behind RF Testing

As wireless communication technologies evolve, RF front-end (RFFE) modules—critical for signal transmission and reception—are becoming increasingly complex. From multi-band smartphones to massive antenna arrays in 5G base stations, these modules contain a variety of components such as power amplifiers (PAs), filters, and switches. However, testing and controlling these devices present several key challenges:

- Fragmented protocols: Coexistence of SPI, I2C, and proprietary interfaces

- Varied voltage levels: Mixed use of 1.8V, 2.5V, and 3.3V

- Diverse clock speeds: Conflicting needs between low-speed debugging and high-speed mass production

Traditional test solutions rely heavily on custom hardware or scattered control modules, resulting in poor compatibility, long development cycles, and low-test efficiency. The industry needs a standardized and flexible control solution. MIPI RFFE is emerging as the unified protocol for RF front-end control interfaces, with dedicated controllers serving as the bridge between test equipment and devices under test (DUT).

2. Understanding MIPI RFFE: The Value of Standardized Control

MIPI RFFE (Radio Frequency Front-End Control Interface), developed by the MIPI Alliance, is a dedicated protocol that offers a reliable, high-efficiency serial interface for RF front-end components. Its goal is simple: enable seamless communication among diverse devices through a unified command language. Key benefits include:

- Standardization and Compatibility

RFFE defines a consistent command set and data format, supporting configuration and monitoring of multiple RF components such as PAs, filters, and switches. With a shared clock (SCLK) and data (SDATA) line, the protocol simplifies hardware design and enables synchronized control across devices. - High Speed and Low Power

The protocol supports two data rate modes—up to 104 MHz for high-speed operations and 13 MHz for low-speed scenarios—adapting to different timing needs. Its half-duplex differential signaling minimizes electromagnetic interference (EMI) and enhances signal integrity in high-frequency scenarios. - Flexible Register Access

Features such as register read/write, masked writes, and extended access allow precise tuning of parameters such as gain, band selection, and power modes—critical for dynamic RF chain configurations.

For enterprises, adopting MIPI RFFE streamlines hardware integration during R&D and enables automated script-based testing in production, significantly boosting efficiency and cutting labor and time costs.

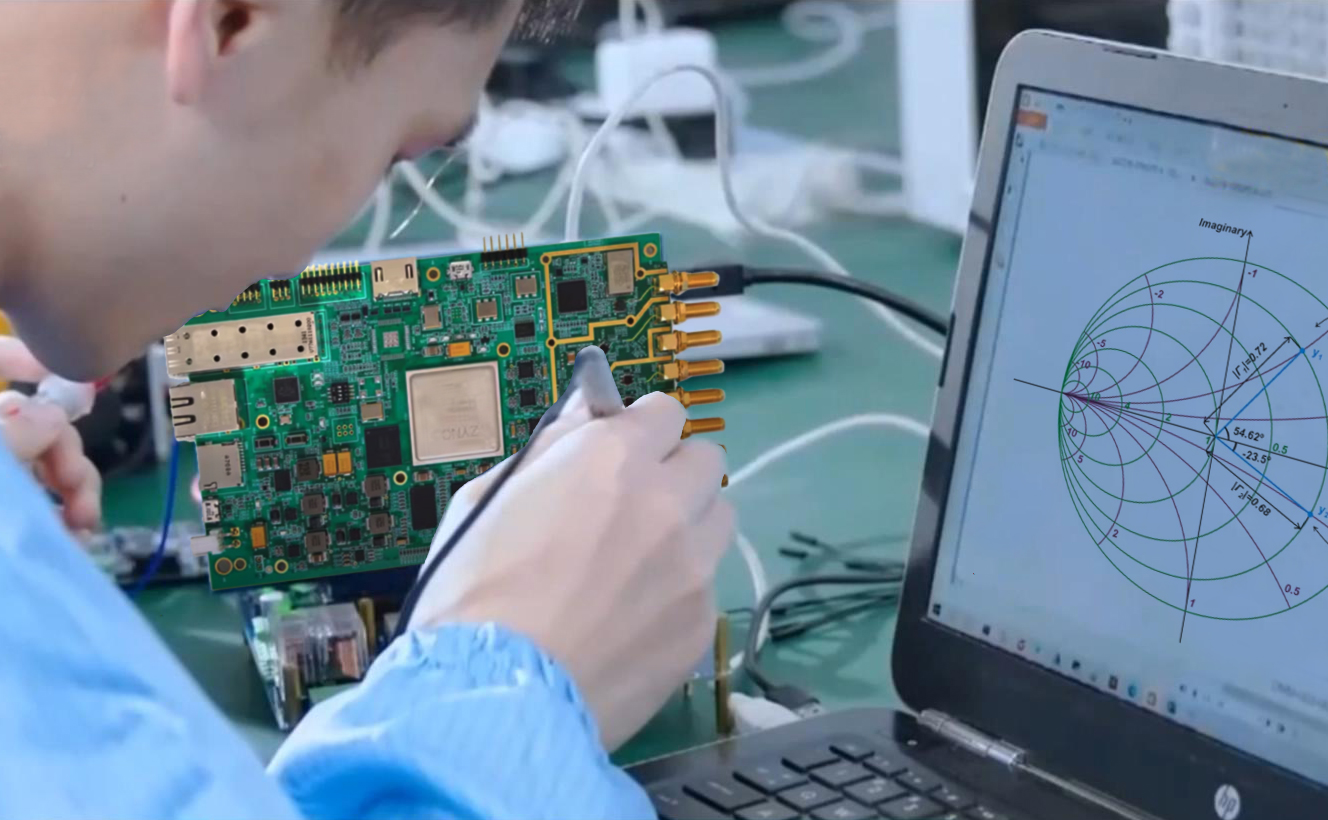

3. SG2674 MIPI RFFE Controller: Bridging Protocol and Hardware

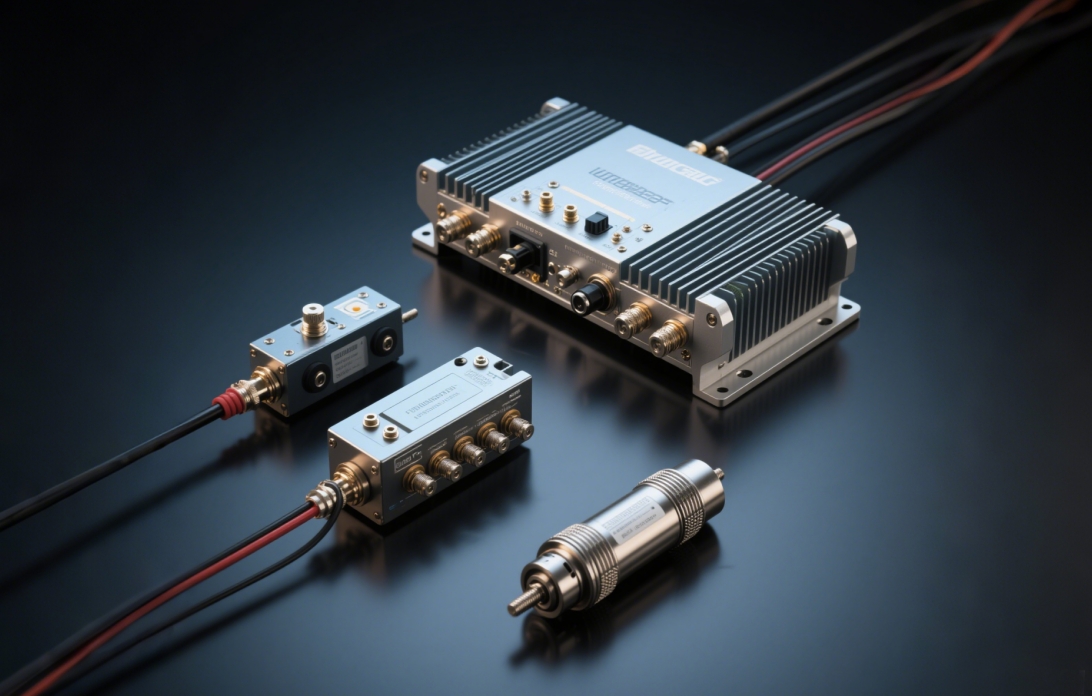

Developed by Smartgiant Technology, the SG2674 MIPI RFFE controller is designed to address the challenges of interface adaptation and protocol conversion in RF front-end testing. Acting as a bridge between a PC (or Mac) and the DUT, it integrates hardware and protocol logic to enable efficient configuration and real-time monitoring.

Powered by the Xilinx Zynq-7000 SoC (XC7Z007S, single-core ARM Cortex-A9), the SG267 controller combines high-performance logic resources with software programmability. Key features include:

- Dual-Channel Parallel Control for Enhanced Throughput

Equipped with two MIPI RFFE channels (DB15 connectors), the SG2674 can simultaneously connect and configure two devices (e.g., a power amplifier and a filter). It supports dynamic clock adjustment (26 MHz for long cables / 52 MHz for short cables) to balance signal integrity and high-speed communication, boosting testing efficiency by 30% compared to single-channel solutions. - Universal Interface Compatibility

Plug-and-play USB 2.0 connectivity and Gigabit Ethernet support (default IP: 169.254.1.37) enable remote control across Windows/macOS systems. Compatible with LabVIEW and Python environments for real-time data feedback.

- Smart Power Management and Voltage Level Adaptation

- Configurable Power Output (Vpwr): Supports custom voltage outputs (available upon request) to accommodate devices with different power requirements, minimizing risk of damage.

- Real-Time VIO Monitoring: Built-in voltage measurement instantly reports I/O reference levels (1.8V/2.5V/3.3V), visually indicated via LEDs, enabling quick diagnosis of voltage mismatch issues and improving debugging efficiency by 50%.

- Industrial-Grade Reliability with Advanced Protocol Support

Built on a Xilinx XC7Z007S SoC, the SG2674 MIPI RFFE controller offers robust protocol processing and real-time control capabilities. It operates reliably across a wide temperature range (0°C to 50°C operating; -40°C to 70°C storage), making it ideal for demanding environments.

Application Scenarios

- R&D Debugging: A Productivity Booster for Engineers

During the development of RF front-end chips or modules, engineers frequently need to adjust parameters such as power gain and band switching logic. The SG2674 connects to multiple devices simultaneously (e.g., PA and filter), enabling real-time register access and status monitoring. Together with host software, it establishes a seamless “configuration–testing–feedback” loop, accelerating both algorithm optimization and hardware tuning.

- Production Testing: Automation Meets Efficiency

Production lines demand both speed and reliability. The controller’s trigger input allows integration with robotic arms, probe stations, and other equipment. Preconfigured scripts can automate tasks such as DUT power-up, protocol initialization, parameter configuration, and performance measurement. Its compact size and industrial durability support continuous operation on automated lines, reducing manual labor.

- Quality Control (QC): Precision Testing for Consistency

In quality control processes, batch testing for consistency is essential. The controller’s mask-write and zero-write features allow rapid device reset to standard conditions, while the real-time voltage monitoring ensures power stability. This helps maintain design compliance across production lots and minimizes risks of missed or false detections.

4. Conclusion: Standardized Testing Tools Powering Industry Innovation

The rise of MIPI RFFE marks a shift toward standardized control in RF front-end testing. As a practical implementation of this technology, the SG2674 controller combines hardware flexibility, protocol compatibility, and intuitive software support to deliver end-to-end solutions for R&D, production, and QC.

Whether you’re an engineer striving for performance breakthroughs or a business manager focused on cost-effectiveness, the SG2674 plays a critical role in improving RF front-end test workflows.

With the continued evolution of 5G and the emergence of 6G, RF front-end complexity is only increasing—driving up expectations for test tools. Smartgiant Technology remains committed to providing high-performance, reliable test and measurement solutions. Let’s tackle future challenges together and accelerate innovation.

Contact Us

Smartgiant Technology 1800 Wyatt Dr, Unit 3, Santa Clara, CA 95054.

Email: info@smartgiant.com

Contact Us

Smartgiant Technology 1800 Wyatt Dr, Unit 3, Santa Clara, CA 95054.

Email: info@smartgiant.com