How FPGA Modules Drive Smart Industrial Automation

Industrial automation is a key driver of modern manufacturing, significantly improving efficiency, quality, and safety by integrating advanced control systems and information technology. In the era of Industry 4.0, automation systems must handle massive data, perform complex computations, and ensure low latency and high reliability. Technologies like FPGAs are becoming essential solutions due to their unique advantages.

This article explores the applications of FPGA modules in industrial automation, highlights their technical benefits and typical use cases, and introduces how Smartgiant’s FPGA products help customers build efficient, flexible, and reliable automation systems—offering valuable insights for engineers, system designers, and tech enthusiasts.

1. Advantages of FPGA Technology in Industrial Automation

FPGA is a programmable hardware device that users can configure into various logic circuits based on specific needs. Compared with traditional microprocessors (CPUs) or microcontrollers (MCUs), FPGAs offer several distinct advantages in industrial automation:

Parallel Processing Capability: FPGAs can perform multiple tasks simultaneously, making them ideal for high-throughput, low-latency applications.

Low Latency: FPGA implementations in hardware logic can achieve response times in the microsecond or even nanosecond range, perfectly suited for real-time control tasks.

Flexibility: FPGAs support reprogramming, allowing users to quickly adapt functionality to meet changing protocol, interface, or algorithm requirements.

High Reliability: Hardware-based implementations reduce the uncertainties of software runtime, improving system stability—especially important for safety-critical applications.

These features make FPGA uniquely suited for industrial automation, particularly in scenarios that demand high real-time performance, computational power, and adaptability.

2. Typical Applications of FPGA Modules in Industrial Automation

FPGA modules are widely used in industrial automation. Below are three core application scenarios, their advantages, and practical examples:

2.1 Real-Time Control

Real-time control is central to the efficient operation of automation systems. For example, in high-speed packaging lines, robotic arms, or CNC machines, precise control over motion trajectory and speed is critical. The parallel processing capability of FPGAs allows control cycles as short as microseconds or even nanoseconds—far superior to traditional microprocessors.

A motion controller based on FPGA can rapidly complete position feedback and speed adjustments at the hardware level, ensuring efficient production line operation and consistent product quality.

2.2 Signal Processing

Industrial automation systems often need to process sensor data in real time, such as vibration signals, temperature data, or image streams. FPGAs are particularly well-suited for implementing complex signal processing algorithms like filtering, Fast Fourier Transform (FFT), or feature extraction.

2.3 Data Acquisition

High-speed data acquisition is another major requirement in industrial automation, especially in testing, measurement, and monitoring scenarios. FPGA modules can capture multi-channel data at high sampling rates and use parallel processing to ensure real-time performance and data synchronization.

For example, in high-speed motor testing, an FPGA can simultaneously acquire data on rotational speed, torque, and temperature, and synchronize these signals with nanosecond precision—providing engineers with a reliable foundation for analysis.

The core advantages of FPGA in industrial automation lie in its hardware-level low latency, parallel architecture, and high sampling rates. These native hardware features deliver much faster computation than purely software-based solutions, making FPGAs an ideal choice for real-time control, signal processing, and data acquisition where both efficiency and precision are essential.

3. Smartgiant’s FPGA Products: Empowering Industrial Automation

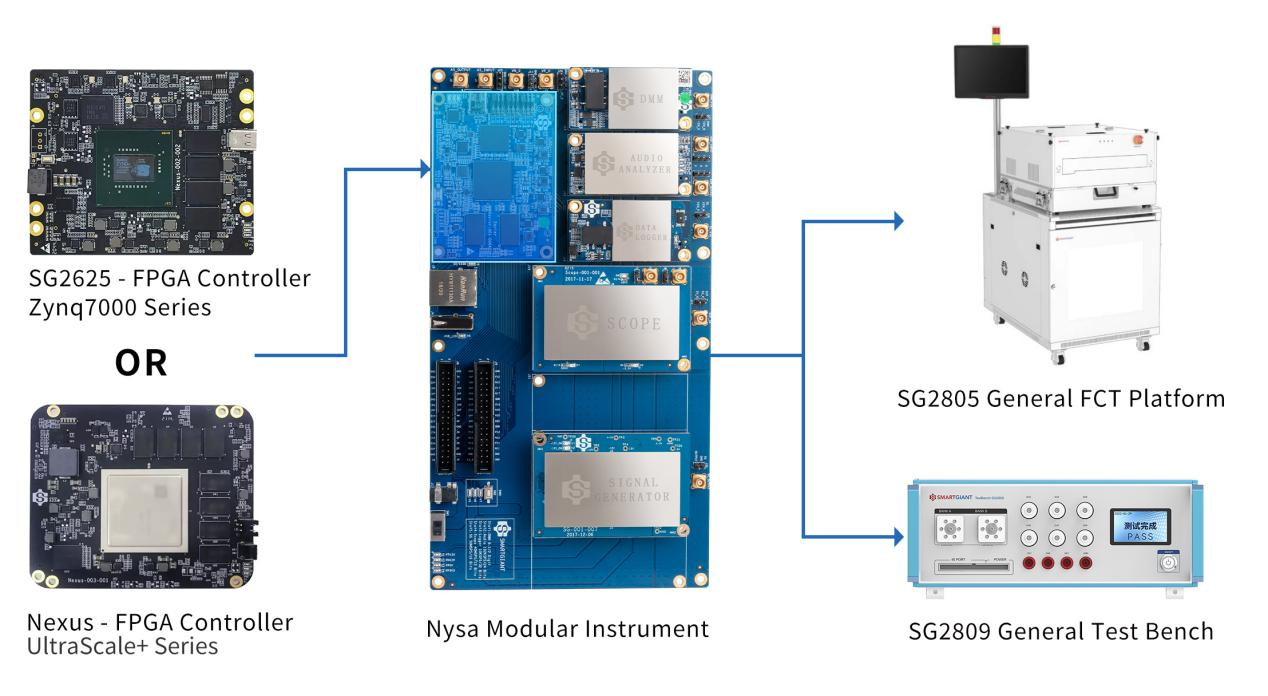

Smartgiant Technology offers high-performance FPGA solutions, including the SG2625 and Nexus series. These modules are based on high-end Xilinx FPGA devices and integrate multi-core ARM Cortex processors, abundant FPGA logic resources, and high-speed interfaces to meet diverse industrial needs.

3.1 SG2625 Series: A Cost-Effective and Flexible Choice

The SG2625 series is based on the Xilinx Zynq 7000 FPGA and integrates a dual-core ARM Cortex-A9 processor with Artix-7 FPGA logic. It offers a balanced solution between performance and cost. Specifications are as follows:

Processor | Memory | Interfaces |

Dual-core ARM Cortex-A9 | 1GB DDR3 | Gigabit Ethernet, USB 2.0, UART |

Dual-core ARM Cortex-A9 | 1GB DDR3 | Gigabit Ethernet, USB 2.0, UART |

Single-core ARM Cortex-A9 | 512MB DDR3 | Gigabit Ethernet, USB 2.0, UART |

Key Features and Benefits:

- High-Performance Processor: The dual-core ARM Cortex-A9 supports complex control algorithms and operating systems, tightly coupled with FPGA logic for software-hardware co-design.

- Compact Design: At just 75mm × 55mm, the module connects to carrier boards via two 120-pin board-to-board connectors, making it easy to integrate into existing systems.

- Flexibility: Rich FPGA logic resources allow custom hardware accelerators and communication interfaces.

The SG2625 series is particularly well-suited for small to mid-scale industrial automation applications that are sensitive to power consumption and cost, such as motion control and data acquisition systems.

3.2 Nexus Series: A Powerful Platform for High-End Applications

The Nexus series is based on Xilinx Zynq UltraScale+ MPSoC FPGAs, integrating a quad-core ARM Cortex-A53 processor, dual-core ARM Cortex-R5 real-time processor, and UltraScale+ FPGA logic. It is designed for high-performance industrial applications. Specifications are as follows:

Processor | Memory | Interfaces | Nexus-001-2EG | 103K | 16GB eMMC | None |

Quad-core Cortex-A53 + Dual-core Cortex-R5 | 2GB DDR4 | Gigabit Ethernet, USB 3.0 Type-C, UART | Nexus-003-7EG | 504K | 16GB eMMC | 24 channels, 16.3Gbps |

Key Features and Benefits:

- Ultra-High Performance: The combination of Cortex-A53 and Cortex-R5 processors supports high-performance computing and real-time processing tasks.

- High-Speed Communication: SerDes channels support data transfer rates up to 16.3Gbps, ideal for high-speed communication and data-intensive applications.

- Abundant Resources: Up to 504K logic cells for implementing complex algorithm acceleration and signal processing.

- Easy Integration: Compact module design and versatile interfaces support fast system integration.

The Nexus series is ideal for industrial automation scenarios that require greater computational power and high-speed communication, such as industrial vision systems and complex process control.

Smartgiant’s core FPGA controller products are also used in complementary production test equipment, such as the Nysa Modular Instrument and SG2809 Test Bench. These form a complete product matrix—from core control modules to production testing—providing full-process support for industrial automation applications.

3.3 Customization Services: From Concept to Mass Production

In addition to standard FPGA modules, Smartgiant offers comprehensive customization services, including:

- Hardware Design: Customizing module specs and interfaces to meet customer requirements.

- Firmware & Software Development: Tailored FPGA logic and embedded software support.

- ODM Services: Full-process support from R&D and validation to mass production, helping customers accelerate time-to-market.

4. Smartgiant FPGA: Empowering Industrial Automation

FPGA modules are transforming the landscape of industrial automation. Their high performance, low latency, and flexibility make them ideal tools for addressing the challenges of modern industry. From real-time control and signal processing to data acquisition and communication interfaces, FPGA applications are vast and impactful.

Smartgiant’s SG2625 and Nexus FPGA module series offer customers a wide range of options. Whether for small-scale applications or high-end demands, there’s a solution to match. Combined with Smartgiant’s customized services, customers can rapidly build efficient, flexible, and reliable automation systems to seize the opportunities of Industry 4.0.

Want to learn more about Smartgiant’s FPGA products? Visit our official website or contact our technical support team. Let’s build the future of intelligent industry together!

Contact Us

Smartgiant Technology 1800 Wyatt Dr, Unit 3, Santa Clara, CA 95054.

Email: info@smartgiant.com

Contact Us

Smartgiant Technology 1800 Wyatt Dr, Unit 3, Santa Clara, CA 95054.

Email: info@smartgiant.com