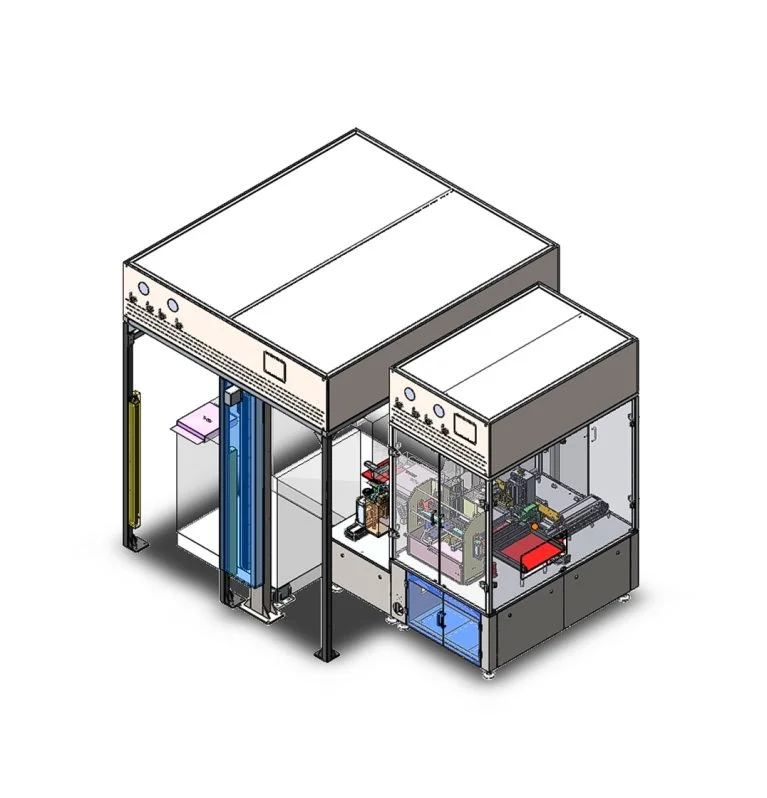

Aseptic Unpacking Machine for Pharmaceutical Workshop

Overview

This equipment is suitable for automated unpacking operations in the aseptic environment of the pharmaceutical industry, providing uninterrupted bottle supply for subsequent automatic filling processes.

It is equipped with an aseptic bottle supply system, a 3D visual recognition system, a robotic arm grabbing system, a waste film recycling system, and a flexible cutting system. These systems ensure the orderly execution of various processes, including automated grabbing, film spreading, film cutting, film pulling, and waste film recycling.

The equipment enables real-time information interaction with the filling system, and automatically matches the bottle output speed with the rhythm of the linked filling system.

Typical Applications

Features

- Realizes automated unpacking operations for the animal vaccine production workshop of a listed pharmaceutical enterprise

- Supports compatibility with three vaccine bottle capacities: 50ml, 100ml, and 250ml

- Adopts flexible cutting method, with a cutting qualification rate of 99.9%

- Bottle inversion rate during the unpacking process is less than 0.01%

- Equipped with an independent O-RABS system to ensure cleanliness during the unpacking process

- Complies with the requirements of the 2020 edition of Veterinary GMP Standards

- Product functional testing FCT

- High-speed bus test solution

- RF front-end test solution

- Software testing solution/FPGA acceleration solution

- PCBA modular universal fixture

- 3C MMI automated testing

- Photovoltaic module aging test

- AI vision industrial application solution

- AI Vision Business Application Solution

Contact Us

Smartgiant Technology 1800 Wyatt Dr, Unit 3, Santa Clara, CA 95054.

Email: info@smartgiant.com

Contact Us

Smartgiant Technology 1800 Wyatt Dr, Unit 3, Santa Clara, CA 95054.

Email: info@smartgiant.com