solution detail

Electrical Signal Processing IP

| Category | Function/Interface | Typical Application |

| Signal generation and measurement | Signal Generator、SMU、LCR、ADC、DAC | High-speed/high-precision signal generation, small-signal measurement, and component parameter measurement |

| Signal processing | Audio、Duty Cycler、PWM、Frequency Counter、AM/FM/PM Modulation | Analog/digital circuit testing, audio testing, frequency characteristic measurement, waveform generation and modulation |

| Protocol analysis | Data Sniffer、Protocol Analyzer、Power Sequence | Bus debugging, communication protocol analysis, and troubleshooting |

| Digital interface IP | PDM、TDM、I2S、I2C/I3C、UART、SPI、QSPI、IO | Embedded system debugging, MCU/SoC peripheral communication verification, and audio interface testing |

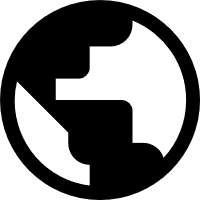

◆ Silingjie’s electrical signal processing IP can realize high-speed and high-precision signal generation and measurement, including small-signal detection and component parameter analysis; it supports diversified signal processing to efficiently complete data capture and protocol parsing; it is compatible with common digital interfaces, eliminates communication bottlenecks, and provides core technical support for customer customization.

Applications of Electrical Signal Processing

◆ The solutions cover multi-form data acquisition products (including PCIe card-type and Box standalone-type), provide customization services ranging from core modules to complete systems, support ODM, and adapt to the personalized needs of industries such as new energy, biomedicine, and aerospace, helping to quickly implement high-performance data acquisition and signal processing applications.

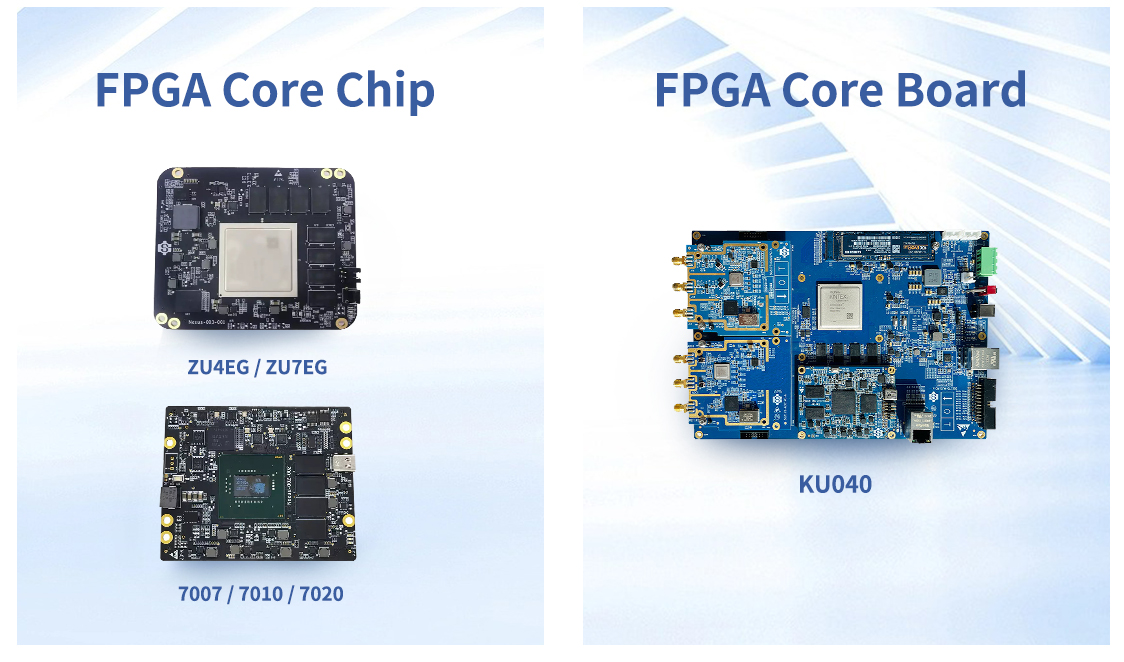

FPGA Core Board

Silingjie IP is developed based on Xilinx’s advanced architecture. It enables R&D teams to quickly focus on the development of core functions and significantly shorten project cycles.

Through secondary development, it can be adapted to international mainstream FPGA brands such as Altera and Lattice, meeting the diverse device selection needs of projects. It also provides in-depth support for domestic FPGA solutions, responding to project requirements for localization adaptation and independent controllability, and fully covering core technical needs in different scenarios.

FPGA IP Solution – High-Speed Interface IP

Based on independently developed FPGA core boards and IP, we have created products such as PCIe high-speed acquisition cards and data acquisition Boxes, possessing full-link capabilities from customized hardware design to mass production and delivery. We support FPGA hardware reconfiguration and in-depth IP customization, enabling parallel advancement of prototype verification, function optimization, and large-scale production, thus achieving full-process coverage from design and verification to batch deployment.

Turnkey Project

A full set of customized hardware-software integrated solutions, covering everything from core components to application scenarios.

We provide complete hardware and software solutions, including core hardware (IP), underlying software (drivers/firmware), functional modules (middleware/applications), and end-user software (upper-layer applications). This enables full-process delivery from component selection and design to mass production, eliminating the need for coordination across multiple parties and making development efficient and hassle-free.

Solution Catalog

- Product functional testing FCT

- High-speed bus test solution

- RF front-end test solution

- Software testing solution/FPGA acceleration solution

- PCBA modular universal fixture

- 3C MMI automated testing

- Photovoltaic module aging test

- AI vision industrial application solution

- AI Vision Business Application Solution

Contact Us

Smartgiant Technology 1800 Wyatt Dr, Unit 3, Santa Clara, CA 95054.

Email: info@smartgiant.com

Contact Us

Smartgiant Technology 1800 Wyatt Dr, Unit 3, Santa Clara, CA 95054.

Email: info@smartgiant.com