Synthetic Biology – High-Throughput Microfluidic Droplet Screening Solution

Features

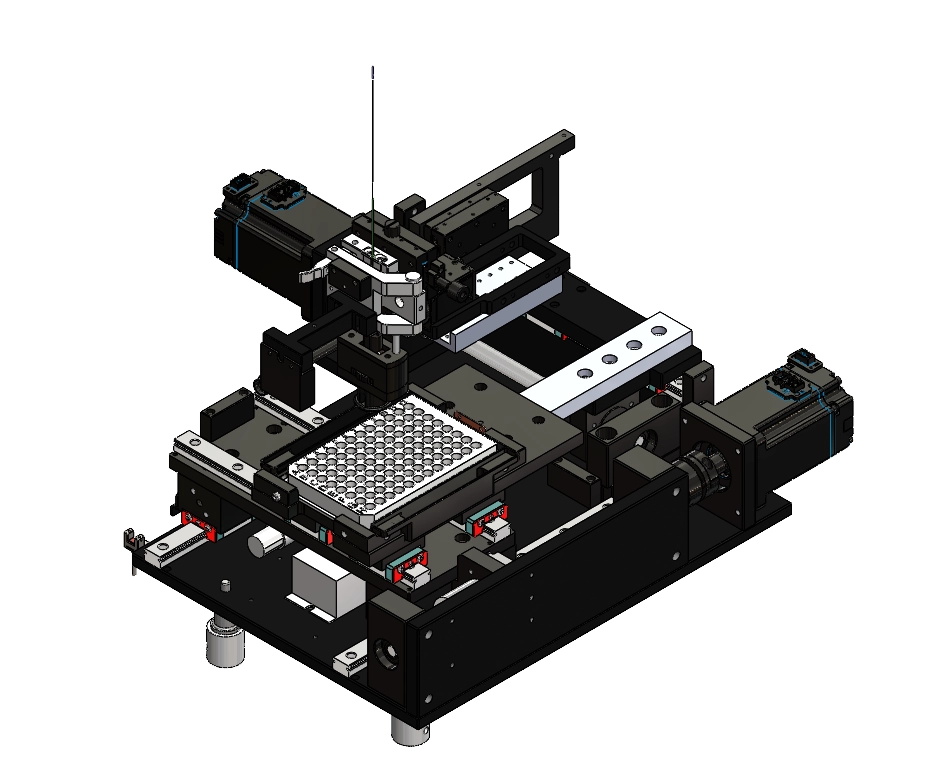

- Multi-functional integration of droplet preparation, sorting, injection & fusion, and printing into wells

- Benchtop design to save valuable laboratory space resources

- Features high-throughput, high-precision, and high-sensitivity droplet screening

- Digital signal processing on multiple platforms such as MCU, ARM, FPGA, DSP, and GPU

- Customized development of upper computer software, enabling richer data display, more elegant interface, and more convenient interaction

- Micron-level single droplet recognition

- Control over the number of droplets injected into wells

- Precise control of printing into specified well positions

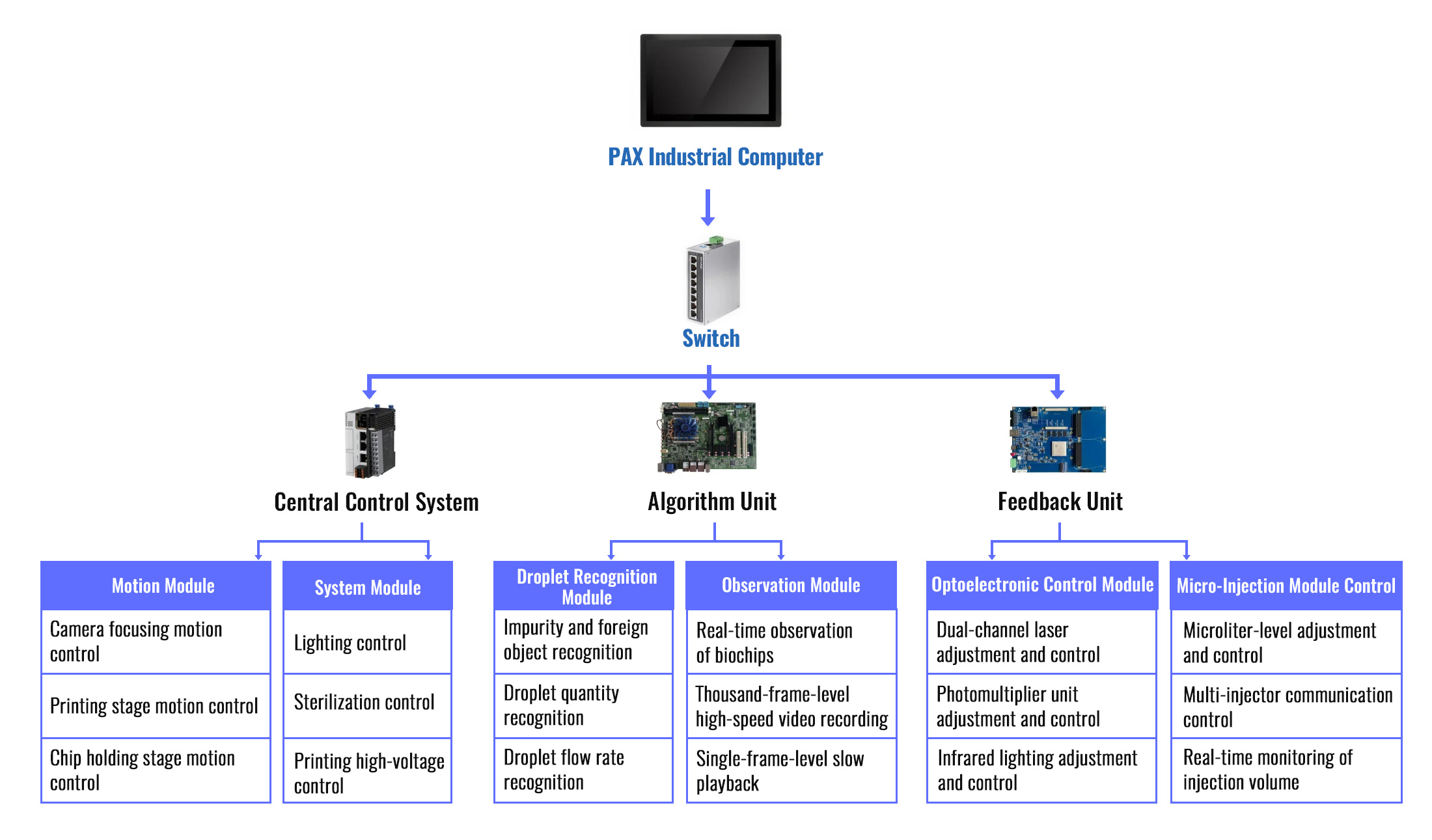

Main Topology Relationship

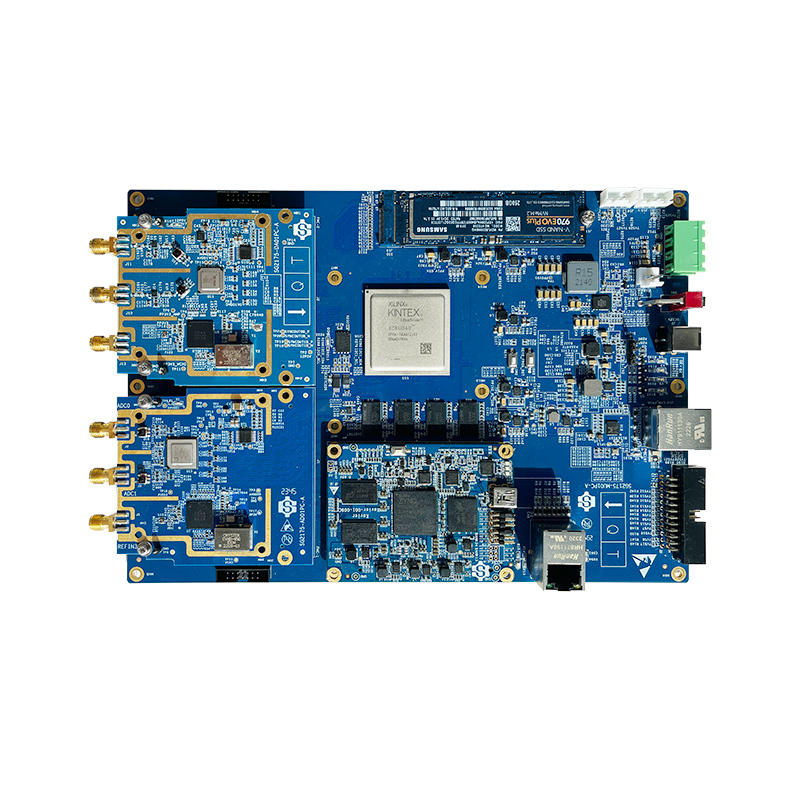

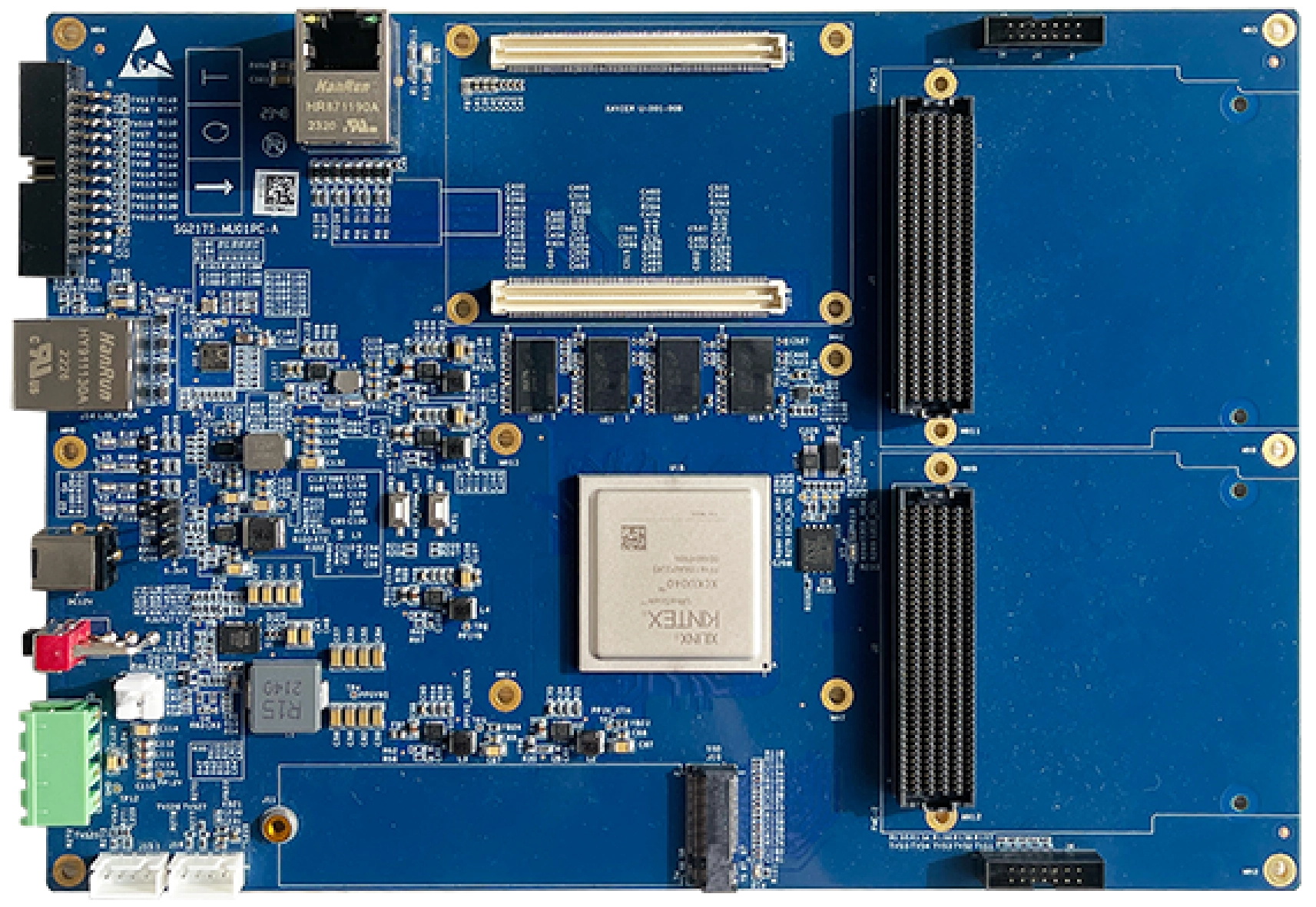

FPGA Control Board

- Adopts industrial standard design: compliant with IEC standards

- 256Mb QSPI Flash, 4GB DDR4

- Supports abundant interface resources, including M.2 SSD interface, JTAG interface, Gigabit Ethernet uplink port, etc.

- Standardized FMC (FPGA Mezzanine Card) high-speed interface design

- Supports customization of hardware interfaces, number of channels, dimensions, etc.

Upper Computer Software

- Development of multi-level management permissions

- Data collection range settings

- Data collection threshold settings and alarms

- Data collection waveform curve settings

- Data collection and storage

- Display of waveform charts, histograms, scatter plots, and heatmaps

- Configuration of overall experiment name, laser wavelength, laser power, sorting parameters, and fluid parameters

- Setting of sorting duration, sorting throughput, positive rate, droplet generation duration, droplet generation throughput, and droplet generation fluid parameters

- Automated operation of process recipes

- Saving of test logs and equipment operation logs

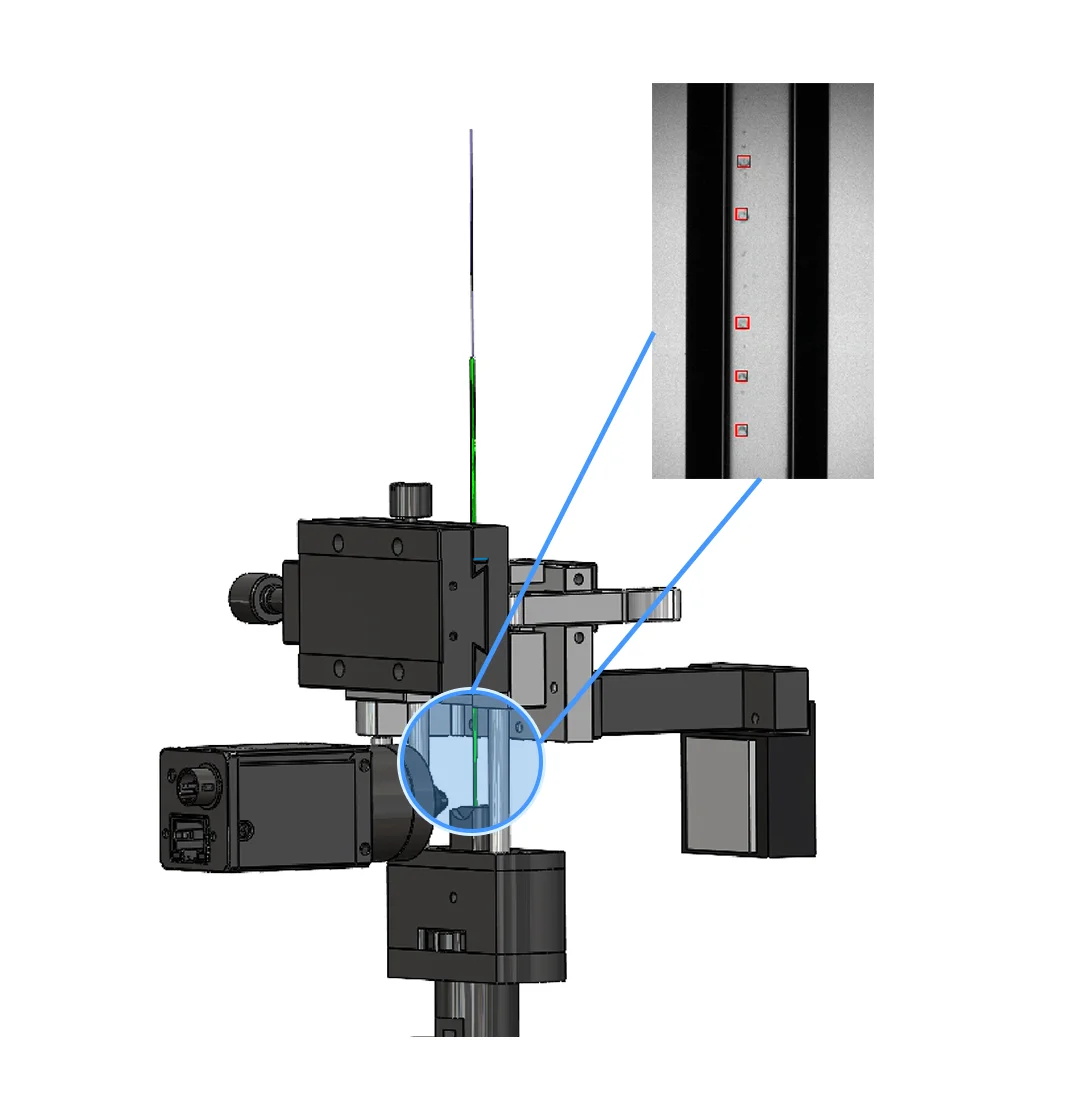

Micro-Droplet Recognition Module

- Capability of detecting and recognizing micron-level droplets, with an identification accuracy of over 98%

- Independent algorithm research and development, supporting sample data iteration

- Miniaturized design to save internal equipment space

- Automatic focusing design to save debugging time

- Excellent detection capability for complex, blurred, and defective images

- Simplified disassembly and assembly design for easy replacement of printing tube consumables

Well Plate Printing System

- Adopts dielectric field technology to realize micro-droplet dragging, ensuring efficient and accurate well injection

- High-precision displacement control to meet the printing requirements of 384/96 well plates

- Miniaturized design to save internal equipment space

- Supports continuous and custom well selection designs

- Simplified well plate picking and placing design to avoid displacement deviation during mobile printing

- Streamlined printing calibration mode for more user-friendly operation

- Waste liquid tank recovery design for effective waste liquid recycling and convenient secondary utilization

Solution Catalog

- Product functional testing FCT

- High-speed bus test solution

- RF front-end test solution

- Software testing solution/FPGA acceleration solution

- PCBA modular universal fixture

- 3C MMI automated testing

- Photovoltaic module aging test

- AI vision industrial application solution

- AI Vision Business Application Solution

Contact Us

Smartgiant Technology 1800 Wyatt Dr, Unit 3, Santa Clara, CA 95054.

Email: info@smartgiant.com

Contact Us

Smartgiant Technology 1800 Wyatt Dr, Unit 3, Santa Clara, CA 95054.

Email: info@smartgiant.com