Data Acquisition (DAQ) and System Solution

1. Introduction to Data Acquisition (DAQ)

1.1 What is Data Acquisition (DAQ)?

Data Acquisition (DAQ) is a cornerstone process in contemporary science and engineering, focusing on the measurement of real-world physical or electrical phenomena and their conversion into digital data. This transformation is critical because physical quantities—such as voltage, current, temperature, pressure, sound, or motion—exist as continuous analog signals, while modern computing systems primarily operate in the discrete digital domain. The central mission of DAQ is to bridge this analog-digital divide, making physical data accessible and usable for computers and digital devices.

The primary objective of DAQ is to collect and analyze data from diverse sources, enabling real-time monitoring, control, quality assurance, process optimization, and troubleshooting across engineering, scientific research, and industrial environments. By converting raw physical variables into actionable digital information, DAQ systems provide deep process insight and control, substantially supporting data-driven decision-making.

The evolution of DAQ systems—from rudimentary data collection to sophisticated, software-driven, multi-channel solutions—spans several decades. A landmark in this history was IBM’s introduction of the 7700 Data Acquisition system in 1963, which marked one of the earliest integrations of computers with data acquisition tasks. This development laid the foundation for today’s complex, automated DAQ systems.

It is essential to recognize that DAQ is more than just a measurement process; it underpins the digital transformation of physical reality. The ability to convert continuous analog phenomena into digital data is fundamental for advanced analytics, automation, and control systems. For example, digital twin technology—where virtual models of physical assets are continuously updated with real-time data—relies entirely on robust DAQ. Without the capacity to digitize vast streams of physical data, many modern innovations would be impossible. DAQ thus serves as the essential enabler for artificial intelligence, machine learning, the Internet of Things (IoT), and complex simulations, providing the raw digital material for intelligent decision-making and autonomous operation across industries.

1.2 The Fundamental Role of DAQ Systems in Modern Industries

DAQ systems are indispensable in contemporary engineering, scientific, and industrial settings. They deliver real-time monitoring and precise control over key parameters such as temperature, pressure, and voltage, which are vital for quality control, process optimization, and effective troubleshooting.

A significant advantage of DAQ systems is their ability to replace subjective evaluation with objective, quantifiable data. In the past, product testing often relied on qualitative assessments—such as a test driver’s subjective impression of a car’s suspension. DAQ systems, by contrast, provide repeatable, mathematically analyzable data, which is crucial for unbiased evaluation of performance, safety, and reliability. This shift from qualitative to quantitative assessment ensures consistency and eliminates human bias from critical evaluations.

By transforming physical variables into digital data, DAQ systems enable deeper understanding and enhanced control of processes. The data collected supports accurate reporting, the development of statistical and machine learning models for prediction or classification, continuous performance monitoring, and secure archiving for compliance and future reference.

The transition from subjective to objective measurement, made possible by DAQ, is foundational to the modern shift toward data-driven decision-making and advanced automation. The objectivity and repeatability of DAQ data are not just about accuracy—they are essential for building reliable, predictable automated systems and closed-loop controls. If measurements were inconsistent or subject to interpretation, automated systems would be unstable, leading to inefficiencies, safety risks, or product defects. DAQ’s contribution is not merely data collection but the provision of trustworthy data that can directly feed into algorithms and automated processes, enabling true autonomy and optimization. This capability is a cornerstone of modern industrial paradigms such as Industry 4.0, where interconnected systems depend on accurate, real-time data for autonomous operation, predictive maintenance, and continuous improvement. It moves industries beyond simple programmed automation to intelligent, adaptive automation, greatly enhancing productivity and reducing operational risks.

2. Core Components of a DAQ System

2.1 Hardware Architecture: Sensors/Transducers, Signal Conditioning, Data Acquisition Devices (ADCs), and Data Loggers/Computers

A DAQ system is a comprehensive setup meticulously designed for measuring and collecting data. It typically comprises several essential hardware components that work in concert: sensors/transducers, signal conditioning circuits, a data acquisition device (including an Analog-to-Digital Converter, or ADC), and a computer or data logger.

Sensors/Transducers: These devices are the initial interface between the physical world and the DAQ system. They detect and measure various physical characteristics—voltage, current, temperature, pressure, sound, motion, strain, weight, or displacement—and convert them into measurable electrical signals. The choice of sensor depends on the parameter being measured; for example, thermocouples for temperature, load cells for weight, and accelerometers for vibration.

Signal Conditioning Circuits: The raw electrical signals generated by sensors are often unsuitable for direct digitization due to low amplitude, noise, or non-linearity. Signal conditioning modifies these signals to ensure accurate conversion. Key functions include:

-

Amplification: Boosting weak signals to a usable voltage for the ADC.

-

Filtering: Removing unwanted noise and interference, including anti-aliasing filtering (AAF), which must be performed in the analog domain to prevent aliasing caused by under-sampling. The cutoff frequency of the anti-aliasing filter should be less than the Nyquist frequency to avoid false signals.

-

Linearization: Correcting non-linear sensor outputs for accurate representation of the measured phenomenon.

-

Isolation: Electrically separating the measurement circuit from interference sources to preserve signal integrity, especially for low-level signals.

Signal conditioning is critical for enhancing signal quality and accuracy, ensuring the signal is precisely prepared for digitization.

Data Acquisition Device (ADC): At the heart of all digital DAQ systems is the Analog-to-Digital Converter. Its primary function is to sample the conditioned analog signals and convert them into digital values for computer processing. Two key ADC parameters are:

-

Resolution: Determines the smallest detectable change in the analog signal (e.g., 16-bit, 24-bit ADCs offer higher amplitude resolution). However, higher resolution is only meaningful if the system’s noise level is sufficiently low.

-

Sampling Rate: The frequency at which readings are taken, crucial for capturing rapidly changing signals. A higher sampling rate yields more data points and a more detailed signal representation.

Computer or Data Logger: This component processes, stores, visualizes, and analyzes the acquired digital data. DAQ systems may be PC-based (USB or PCI-Express), standalone/portable (with built-in storage and display), or networked. Modern DAQ devices often include non-volatile memory, ensuring data retention even in the event of power loss, which is vital for data integrity.

The accuracy and reliability of DAQ data depend not only on the ADC but on the entire hardware chain, with signal conditioning playing a crucial—often underestimated—role. The ADC can only digitize the signal it receives. If the sensor signal is noisy, too weak, or outside the ADC’s optimal range, even a high-resolution ADC will yield inaccurate or meaningless data. This is the “garbage in, garbage out (GIGO)” principle: poor-quality input cannot be corrected by digital processing. Therefore, robust and appropriate signal conditioning is as important as ADC specifications, especially in harsh industrial environments. The quality of data analysis is directly tied to the quality of the input data from the analog front-end. This highlights a common oversight: focusing on digital processing power or ADC resolution while neglecting analog signal integrity. Poor analog quality cannot be fully corrected digitally, limiting system accuracy, reliability, and the trustworthiness of insights. A balanced, holistic design approach is essential.

2.2 Software: The Brains Behind the Hardware

DAQ software is an integral part of any data acquisition system, serving as the interface that unlocks the hardware’s capabilities and transforms raw data into actionable information.

Key functions include:

-

Data Collection & Configuration: Enables data capture from diverse sources and provides intuitive tools for configuring measurement channels, setting sensor parameters, ranges, and trigger criteria (such as alarms or thresholds).

-

Real-time Monitoring & Visualization: Offers immediate visual feedback in various graphical formats (waveforms, bar graphs, FFTs, strip charts, histograms, data grids, numerical displays), crucial for observing system behavior, detecting anomalies, and making operational decisions.

-

Data Logging & Storage: Securely records and stores large volumes of data, supporting various formats and storage options (local or cloud-based), with modern devices often featuring non-volatile memory for data integrity.

-

Data Analysis & Processing: Provides built-in analytical tools for mathematical/statistical calculations and report generation. Supports both time-domain and frequency-domain analysis and allows non-destructive post-measurement filtering. Supports creation of “virtual channels” by applying mathematical functions to real-time data.

-

Control & Automation: Integrates control and automation features, allowing users to interact with devices, set triggers/alarms, and execute predefined actions. Can coordinate actions across multiple DAQ systems and control programmable power supplies, enabling automated test sequences.

-

Scalability & Integration: Supports multiple DAQ systems and modules, with firmware that identifies and integrates diverse modules. Offers robust integration with external systems, specialized analysis software, and programming languages for custom workflow development.

Modern DAQ software goes far beyond simple data logging. It is the critical layer enabling complex system configuration, real-time intelligence, and seamless scalability across diverse hardware and multiple DAQ units. The sheer volume and variety of data in modern DAQ systems—ranging from dozens to thousands of channels—would be unmanageable without sophisticated software. Its ability to configure, synchronize, and process data from disparate sources, and to define “virtual channels” (derived from raw data), makes it an active, intelligent orchestrator of measurement and analysis. This orchestration allows DAQ systems to scale from simple benchtop setups to complex, multi-rack industrial deployments, providing unified control and streamlined operations. The software’s intelligence in data validation, triggering, and integration with enterprise systems is increasingly the primary differentiator for DAQ solutions, unlocking the full potential of the hardware.

3. Conclusion

DAQ systems are indispensable in modern industry and research, enabling objective, real-time, and accurate digitization of physical phenomena. Their effectiveness relies on a balanced integration of robust hardware—sensors, signal conditioning, ADCs, and data loggers—and intelligent software for configuration, visualization, analysis, and automation. This comprehensive approach ensures high-quality data, forming the foundation for advanced analytics, automation, and digital transformation across sectors.

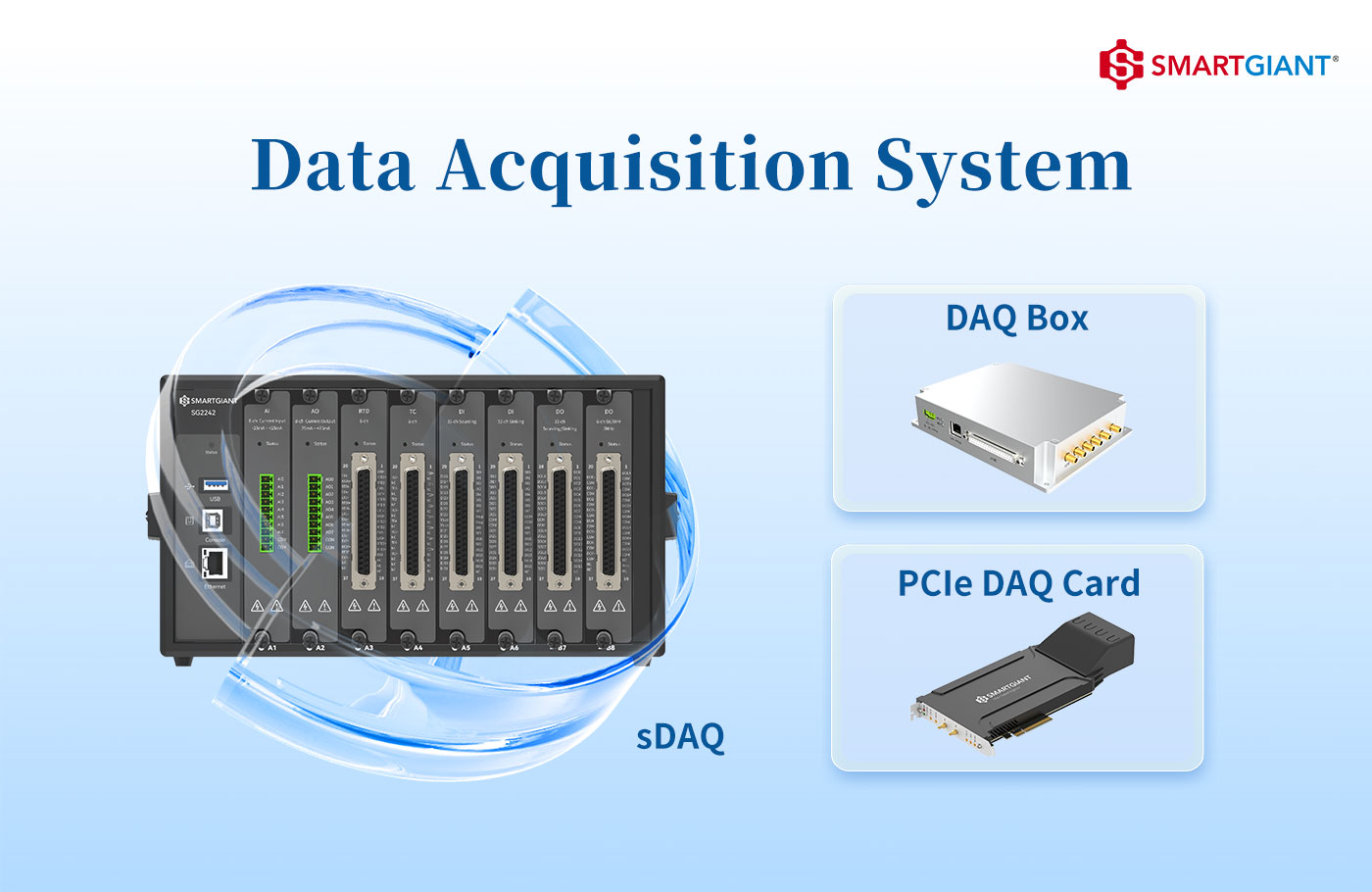

Data Acquisition Device Boost Profit – Consider other products?

Data Acquisition Device Cut Down Cost – View Other Pages

More About Data Acquisition Device

Experience Smartgiant Technology firsthand, have a look at the most unparralleled data acquisition device here! Smartgiant Technology has a long history and experience of providingdata acquisition device, which means we are qualified and skilled. With a long history in this market, we have accumulated a substantial workforce, operate a spacious factory, and maintain a significant monthly production capacity. Our data acquisition device are worth buying. Quality assurance is at the core of our operations, with strict testing standards, standardized production processes, and comprehensive quality management in place to safeguard the excellence of our data acquisition device. Moreover, as a skilled, we have a multitude of experience of data acquisition device and have gain great reputation. We have partnerships with abundant collaborators from numerous countries. Our primary sales areas encompass virtually all corners of the globe. We always believe that your request is our command!If you are looking for a customer-focused teammate, consider us right now!

Leave a Reply